n the realm of garment manufacturing, fabric sourcing plays a pivotal role in determining the success and quality of the final product. The process of procuring the right fabrics for your garments can be complex and challenging. However, with our comprehensive guide, you will gain a deep understanding of fabric sourcing, enabling you to make informed decisions and excel in the competitive fashion industry.

What is Fabric Sourcing

Fabric is a crucial component in making clothes. Fabric sourcing involves the careful selection and acquisition of suitable fabrics for garment production. It encompasses various aspects, including identifying the right fabric types, evaluating suppliers, negotiating prices, ensuring quality standards, and managing the supply chain effectively. Effective fabric sourcing involves a delicate balance between cost, quality, reliability, and sustainability. By optimizing each aspect, businesses can gain a competitive edge and foster long-term success.

Importance of Fabric Sourcing

Fabric sourcing directly impacts the quality and performance of garments. It is the main material used in garments and has a significant impact on their quality and cost. In fact, the cost of fabric typically makes up around 60-70% of the total cost of a garment. Fabric sourcing plays a significant role in the manufacturing of garments as designers meticulously incorporate fabric texture, color, and weight into their intricate sketches. The choice of fabric determines how well a garment fits, feels, and withstands wear and tear. By sourcing high-quality fabrics, garment manufacturers can enhance customer satisfaction, build brand reputation, and increase the longevity of their products. Additionally, fabric sourcing has financial implications, as the cost of fabrics significantly affects the overall production expenses.

Factors to Consider in Fabric Sourcing

Type of Fabric you need

The best way to find the type of fabric is to have a plan and design sketches of the garments you want to produce. This allows you to see what materials will work best for each garment.

There are two main categories of fabrics: those made with natural fibers and those made with synthetic fibers. Within each category, there are further subcategories depending on how the fabric was produced (woven vs. knitted fabric).

Knit fabrics

Knit fabrics are produced by interlocking loops of yarn, which allows the fabric to stretch, making knit garments more comfortable to wear. Additionally, breathability is increased in knit fabrics since their construction allows air to circulate more quickly than other types of fabric.

Woven fabrics

Woven fabrics are created by passing warp and weft yarns over and under at right angles. The weave pattern used will affect the properties of the fabric. For example, a twill weave is stronger and more resistant to tearing, while a satin weave has a smoother surface with a lustrous sheen. Woven fabrics don’t usually stretch, so they might not be as comfortable to wear as knit fabrics.

Quality and Performance

When sourcing fabrics, it is crucial to prioritize quality and performance. Different garment designs require specific fabric characteristics such as durability, flexibility, breathability, and colorfastness. Evaluating fabric samples, conducting tests, and seeking certifications can help ensure that the selected fabrics meet the required standards.

Cost and Budget

Cost considerations play a vital role in fabric sourcing decisions. Balancing quality and cost is essential to maintain competitiveness in the market. Manufacturers need to evaluate fabric prices, compare quotations from different suppliers, and negotiate for favorable terms to optimize their budget and profitability.

Sustainability and Ethical Considerations

As sustainability gains prominence in the garment industry, sourcing fabrics with minimal environmental impact and ethical production practices is essential. Manufacturers are increasingly looking for sustainable alternatives such as organic, recycled, or low-impact fabrics. Assessing supplier certifications, transparency in the supply chain, and compliance with labor standards are crucial for responsible fabric sourcing.

Availability and Lead Time

The availability of fabrics and lead time are critical factors in meeting production deadlines. Depending on the time of year and the fabric’s popularity, it may not be readily available. If you need a large fabric, ask the vendor if they can accommodate your order.

Manufacturers need to consider the lead time required for sourcing fabrics, especially when dealing with international suppliers or specialized fabrics. A reliable supply chain and effective communication with suppliers help prevent delays and ensure timely production.

Supplier relationship management

It is crucial in the fabric sourcing process. Building strong relationships with suppliers ensures a reliable supply of quality fabrics, fosters collaboration, and enhances communication. It leads to better quality assurance, cost savings, flexibility, and risk mitigation. Additionally, strong supplier relationships contribute to innovation and continuous improvement in fabric sourcing. Overall, effective supplier relationship management is vital for success in the fabric sourcing industry.

Types of Fabric Sourcing Process

Fabric sourcing can be done through various channels, depending on the requirements and preferences of manufacturers. Here are the main types of fabric sources commonly used in the garment industry:

Local Suppliers

Fabric is manufactured locally, with local infrastructure. Local suppliers offer proximity advantages, shorter lead times, and potential cost savings on shipping. They enable manufacturers to have closer collaboration and more frequent communication, ensuring smoother fabric sourcing processes.

International sourcing

Fabric is made locally, but raw yarn or fiber is sourced from other countries dealing with international suppliers requires careful evaluation, considering factors such as language barriers, cultural differences, shipping logistics, and potential customs regulations.

Global sourcing

Global sourcing in the fabric sourcing process refers to the practice of procuring textile materials from international suppliers or regions outside of the domestic market. It has become increasingly prevalent in today’s globalized economy due to various factors such as cost advantages, access to specialized materials, and market expansion opportunities.

Online Fabric Sourcing Platforms

The rise of e-commerce has also impacted fabric sourcing, with the emergence of online fabric marketplaces. These platforms provide manufacturers with a vast selection of fabrics from various suppliers worldwide, allowing for convenient browsing, price comparisons, and direct ordering. Some reputed online fabric-sourcing platforms are:

Merchant Bay is a tech-enabled fashion sourcing platform. That creates a critical channel for buyers to explore suppliers to source apparel from Bangladesh. Our multisided platform enables both buyers and suppliers to start doing business fast, manage orders with efficiency and grow together simultaneously.

Sewpot: It is a digital platform to help you source high-quality clothing manufacturers and suppliers. From sketch to production and everything in between.

Go sourcing is a Global B2B Networking and sourcing Platform Exclusively for Sourcing Yarn, Fabric, Apparel, Trims, Accessories, Dyestuff and chemicals.

Material Exchange is transforming the way the fashion industry sources materials by building the best fashion sourcing team in the industry who, utilizing our software, helps brands make smarter, more sustainable choices in a fraction of the time.

Navigating the Fabric Suppliers

Wholesale: These bulk-buying champions offer a vast array of fabrics at competitive prices. Think of them as your one-stop shop for common materials like cotton and polyester. However, be prepared for minimum order quantities and limited customization options.

Jobbers: These resourceful suppliers unearth hidden gems – remnants and overstocked fabrics from factories. While offering incredible deals, their stock is fleeting. If a fabric catches your eye, seize it, for it may not reappear.

Traders: Operating in manufacturing hubs like China and India, traders act as intermediaries, connecting buyers with fabric mills. Their expertise lies in securing competitive prices and navigating international logistics.

Fabric Mills: These dedicated artisans transform raw materials into exquisite textiles. Specializing in specific materials like silk or linen, they offer unparalleled quality and control over the production process. However, minimum order quantities and longer lead times may be involved.

Agents: These industry insiders leverage their deep connections with mills to negotiate exceptional deals. Often working on commission, their motivation lies in securing the best value for their clients. Think of them as your personal fabric Sherpas, guiding you through the intricate terrain of sourcing.

Trade Shows: Immerse yourself in a vibrant tapestry of textiles at industry trade shows. Touch, feel, and compare fabrics firsthand, network with suppliers, and discover the latest trends. It’s a sensory overload in the best possible way, igniting your creative spark and fueling your design decisions.

Word-of-Mout: Seek advice from trusted veterans in the garment industry. Their firsthand experiences with different suppliers can lead you to hidden treasures or steer you clear of pitfalls. Consider it insider knowledge passed down from seasoned fabric warriors.

The Online Oasis: The internet offers a vast array of online fabric suppliers, catering to every need and budget. Narrow your search by fabric type, color, and price to find the perfect match. However, remember to request samples and carefully assess quality before committing to larger orders.

Remember, the ideal fabric supplier isn’t a monolithic entity, but rather a strategic combination of sources. Utilize the strengths of each type, from the bulk-buying power of wholesalers to the specialized expertise of mills.

You can also directly send your fabric requirements to us. Send us the following specifications of your fabric our expert sourcing specialist will help you with that.

- Fabric Type

- Fabric Composition

- Yarn Count

- Color

- Finish

- G.S.M.

- Quantity in Yards

Tell us about your requirements

Building Relationships with Fabric Suppliers

Establishing strong relationships with fabric suppliers is crucial for successful fabric sourcing. Collaborative partnerships enable effective communication, a better understanding of each other’s requirements, and more favorable terms. The following steps can help in building relationships with fabric suppliers:

Communication and Collaboration

Regular and open communication is key to fostering strong relationships with fabric suppliers. Clearly communicating product specifications, expectations, and timelines can avoid misunderstandings and ensure alignment between manufacturers and suppliers. Collaboration throughout the fabric sourcing process promotes mutual trust and facilitates problem-solving.

Supplier Evaluation and Selection

Thoroughly evaluating potential suppliers is essential to ensure their reliability and ability to meet quality, quantity, and sustainability requirements. Assessing factors such as reputation, past performance, certifications, and financial stability can help in selecting the most suitable fabric suppliers.

Negotiation and Contracting

Negotiating prices, terms, and conditions with fabric suppliers is a critical step in fabric sourcing. Manufacturers should aim for fair and competitive pricing while considering factors like order volumes, payment terms, and long-term partnership possibilities. Clearly defined contracts protect both parties’ interests and provide a framework for future collaborations.

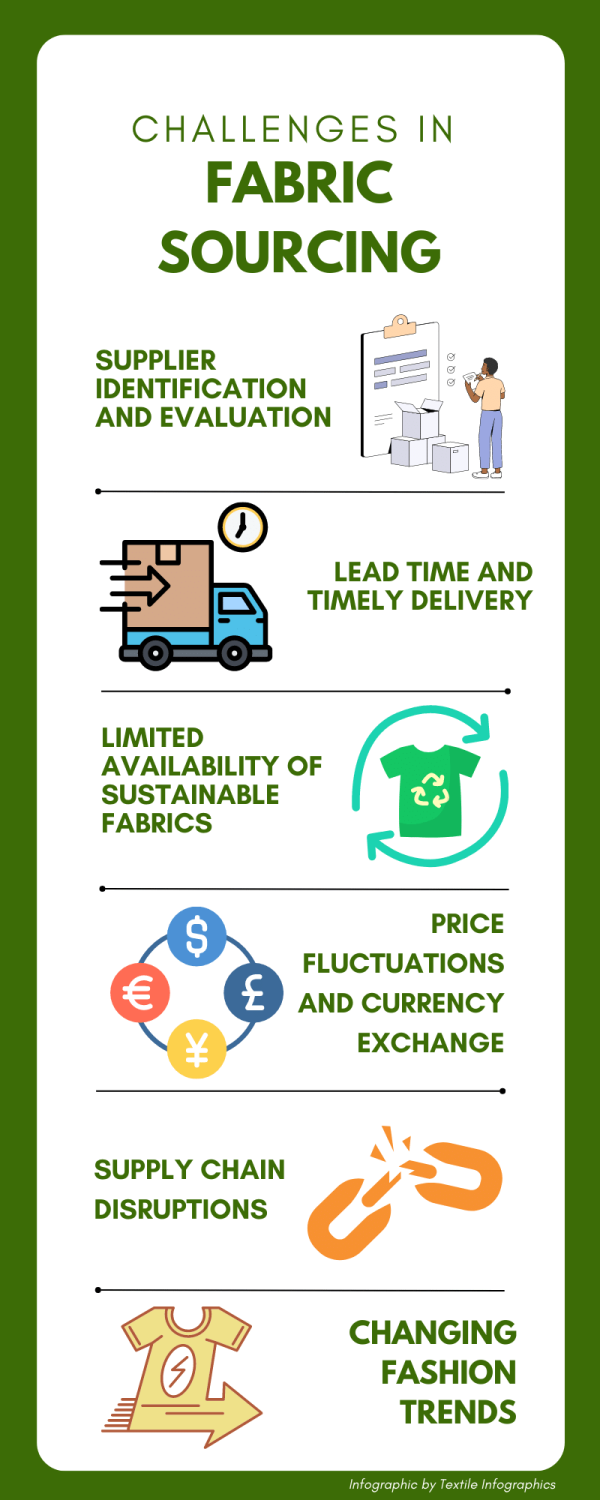

Challenges in Fabric Sourcing

Fabric sourcing in the garment industry presents several challenges that manufacturers need to navigate. Being aware of these challenges and developing appropriate strategies can help overcome them effectively. Some common challenges include:

Supplier Identification and Evaluation

Finding reliable suppliers who can meet specific fabric requirements can be a daunting task. It requires thorough research, evaluation, and due diligence to identify suppliers with the necessary capabilities, quality standards, and ethical practices.

Lead Time and Timely Delivery

Meeting production timelines is crucial for businesses. Delays in fabric sourcing can disrupt the entire production process, leading to missed deadlines and potential customer dissatisfaction. Coordinating with suppliers, managing production schedules, and closely monitoring lead times are necessary to ensure timely delivery.

Limited Availability of Sustainable Fabrics

While the demand for sustainable fabrics is increasing, their availability remains limited. Manufacturers may face difficulties in sourcing sufficient quantities of organic, recycled, or eco-friendly fabrics, particularly for larger production volumes. Collaboration with suppliers, exploring alternative materials, and proactive planning can mitigate this challenge.

Price Fluctuations and Currency Exchange

Fabric prices are subject to fluctuations influenced by factors such as raw material costs, market demand, and currency exchange rates. Manufacturers need to stay updated on market trends, forecast price changes, and incorporate flexibility in their fabric sourcing strategies to manage cost variations.

Supply Chain Disruptions

Disruptions in the fabric supply chain can have a significant impact on production timelines and costs. Natural disasters, political unrest, and global events can disrupt transportation, delay deliveries, or even result in fabric shortages. Building resilient supply chains, diversifying sourcing options, and maintaining clear communication with suppliers are essential in mitigating such disruptions.

Changing Fashion Trends

Fabric sourcing needs to align with evolving fashion trends and consumer preferences. Staying up-to-date with market trends, anticipating shifts in demand, and proactively sourcing fabrics that align with current and future fashion trends is crucial for remaining competitive in the industry.

Strategies for Efficient Fabric Sourcing

Efficient fabric sourcing involves strategic planning and streamlined processes. Here are some strategies to enhance the effectiveness of fabric sourcing in the garment industry:

Analyze the need of sourcing

Identify the need for sourcing. Ask as many questions as you can ask your team and your customers. Know and understand your current business scenario. Set your current situation as a benchmark and analyze the need for sourcing in your business.

Evaluate the supplier’s market

Be careful while choosing a supplier. Often, organizations end up paying for a supplier’s inability. That’s why any apparel business needs to evaluate suppliers based on their previous performance. Before you finalize with any supplier, consider their financial statements, credit reports, and references. Understand the supplier’s working pattern and how well they can match with yours.

Diversifying Fabric Sources

Relying on a single fabric supplier increases the risk of disruptions. Manufacturers should diversify their fabric sources by establishing relationships with multiple suppliers. This helps ensure a stable supply of fabrics, provides alternative options, and reduces vulnerability to market fluctuations.

Preparing Fabric Sourcing Plans

Developing comprehensive fabric sourcing plans helps manufacturers outline their fabric requirements, identify potential suppliers, and establish timelines. These plans consider factors such as fabric quantities, lead times, quality standards, and sustainability goals. Proactive planning minimizes last-minute sourcing challenges and improves overall efficiency.

Streamlining the Procurement Process

Efficient procurement processes save time, reduce errors, and optimize costs. Implementing digital tools for fabric sourcing, automating order placements and tracking, and utilizing inventory management systems contribute to smoother procurement operations. Streamlining processes enables manufacturers to focus on other critical aspects of garment production.

Future Trends in Fabric Sourcing

Fabric sourcing in the garment industry continues to evolve, driven by technological advancements, sustainability concerns, and changing consumer preferences. Here are some future trends to watch for:

Digitalization and Automation

Digitalization and automation are expected to play a significant role in fabric sourcing. From AI-powered fabric recommendation systems to automated order processing, digitizing fabric sourcing processes improves efficiency, accuracy, and speed. It enables manufacturers to make data-driven decisions and adapt to changing market demands.

Blockchain for Transparency

Blockchain technology holds the potential to enhance transparency and traceability in fabric sourcing. By recording every step of the supply chain, from fabric production to garment manufacturing, blockchain ensures visibility and accountability. Consumers can access detailed information about the fabric’s origin, production processes, and sustainability credentials.

Circular Economy and Recycled Fabrics

As sustainability becomes a priority, the adoption of circular economy principles in fabric sourcing is expected to grow. Manufacturers are exploring recycling technologies, promoting closed-loop systems, and sourcing fabrics made from recycled materials. Circular economy practices reduce waste, conserve resources, and contribute to a more sustainable garment industry.

Conclusion

Fabric sourcing is a critical aspect of the garment industry, impacting the quality, cost, and sustainability of clothing production. By prioritizing factors such as fabric quality, cost, availability, and sustainability, manufacturers can ensure the selection of suitable fabrics that meet their requirements. Building strong relationships with fabric suppliers, leveraging technology, and staying updated on industry trends enable efficient and successful fabric sourcing. The fabric sourcing landscape is evolving with the integration of online platforms. These platforms leverage technology to streamline and enhance the fabric-sourcing process. As the industry continues to evolve, embracing future trends like digitalization, blockchain, and circular economy practices will shape the future of fabric sourcing.

FAQs

How to source fabric?

To source fabric you can, attend trade shows or search online for a suitable fabric supplier. Contact the supplier to establish a partnership and include them in your supply chain for a consistent supply of high-quality fabrics.

How to source fabric wholesale?

To source fabric wholesale, start by researching reputable suppliers through online directories, trade shows, and referrals. Contact potential suppliers, and inquire about their product range, pricing, and terms.

How can I stay updated on fabric sourcing trends?

Staying updated on fabric sourcing trends can be done by following industry publications, attending trade shows and conferences, joining professional networks, and engaging with fabric suppliers. These sources provide insights into emerging technologies, sustainability initiatives, and market developments.

What role does technology play in fabric sourcing?

Technology plays a significant role in fabric sourcing, offering tools for fabric selection, supplier management, order tracking, and virtual sampling. Fabric sourcing software, online fabric libraries, and virtual fabric sampling enhance efficiency, collaboration, and decision-making.